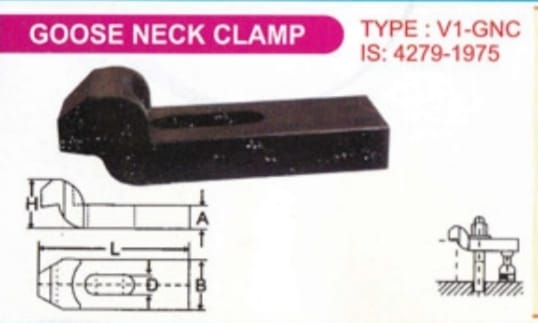

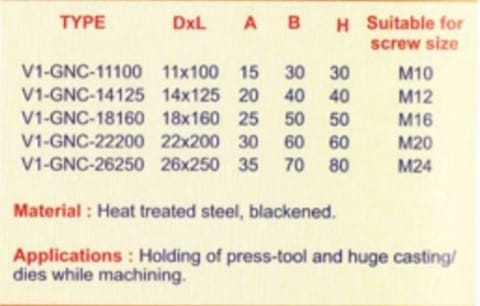

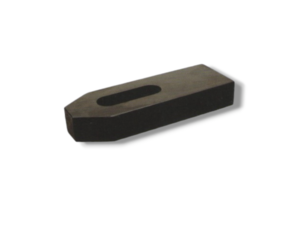

🔧 Features of Goose Neck Clamps

- Goose-neck shaped body: curved design allows clearance over obstacles and workpieces.

- High-tensile steel construction: strong enough to withstand heavy clamping forces.

- Slotted design: enables position and length adjustment.

🛠️ Uses of Goose Neck Clamps

- Used to clamp workpieces on milling, drilling, and CNC machines where clearance is required.

- Helps hold moulds or dies on injection moulding and die casting machines.

- Suitable for fixtures and jigs where ordinary flat clamps can’t be used due to obstruction.

- Common in automotive, aerospace, and tooling industries for precision clamping.

⚙️ Installation of Goose Neck Clamps

- Place the workpiece or mould on the machine bed/platen.

- Position the goose neck clamp so that the nose presses the workpiece/mould.

- Insert a T-bolt or stud through the clamp’s slot into the machine table’s T-slot.

- Support the rear end of the clamp on a step block or spacer for proper height adjustment.

- Tighten the nut/washer to apply downward pressure.

✅ Advantages of Goose Neck Clamps

- Provides clearance: allows tool access over workpiece projections where flat clamps can’t be used.

- Strong and stable: applies uniform clamping pressure.

- Adjustable: works with step blocks to handle various heights.

- Durable and reusable: suitable for heavy-duty operations.

- Reduces vibration during machining, improving accuracy and tool life.