🔧 Features of Serrated Clamps

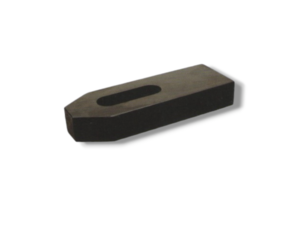

1. Serrated (toothed) surface: Increases grip on the workpiece.Prevents slippage during machining or other operations.

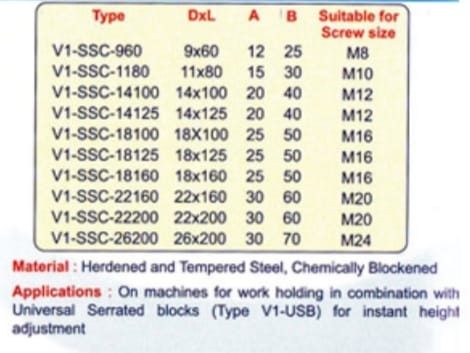

2. High-strength construction: Usually made from hardened steel or alloy for durability and strength.

3. Precision-engineered teeth: Ensures consistent clamping force setups.

🛠️ Uses of Serrated Clamps

1. Machining operations (milling, drilling, CNC): To hold workpieces securely on machine beds or tables.

2. Tool and die making: For precision and repeatability.

3. Welding and fabrication: Prevents shifting of metal parts during welding.

4. Assembly lines: For consistent clamping in jigs and fixtures.

5. Inspection setups: To hold items securely during measurement or testing.

⚙️ Installation of Serrated Clamps

1. Prepare the base: Clean the machine bed or clamping surface.Insert T-bolts or studs into the machine table’s T-slot.

2. Position the clamp: Place the serrated clamp over the workpiece and align it properly.

3. Add a step block or spacer (if needed): Adjust height with step blocks to match workpiece level.

4. Tighten: Use a nut or handle to tighten the clamp onto the bolt/stud, locking the workpiece in place.

5. Double-check alignment and security before starting the machine.

✅ Advantages of Serrated Clamps

1. Strong grip: The serrated edges prevent the clamp from slipping under load.

2. Stable and reliable: Ideal for high-precision machining or fabrication where vibration or movement is a risk.

3. Reusable and long-lasting: Made of durable materials, suitable for repeated use.

4. Versatile setup: Works with various accessories like step blocks, studs, and T-slot bolts.

5. Quick setup: Fast installation and adjustment compared to custom fixtures.